PC Products

PC Products

Displayper page

Sort by

PC Products - 128114 PC-11 Two-Part Marine Epoxy Adhesive Paste, Off White, 8 lb in Two Cans

Two-part marine epoxy adhesive paste bonds materials in dry, wet, and underwater environments | Bonds many materials, including fiberglass, concrete, many metals, glass, ceramic, and rubber | Can be used in indoor and outdoor applications, with a temperature range of 35 to 115 degrees F and a service temperature range -20 to +200 degrees F | High-tack paste can be used in vertical and overhead applications | Resists mild acids, caustics, detergents, gasoline, fuel oil, and fresh and salt water

₹15,014.94

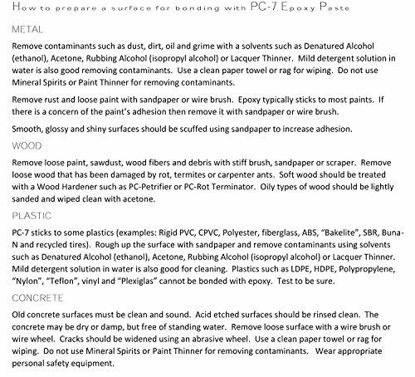

PC Products PC-7 Epoxy Adhesive Paste, Two-Part Heavy Duty, 10gal in Two Pails, Charcoal Gray 909072

Two-part multipurpose epoxy adhesive paste works as a bonding agent, sealant, and filler for a range of indoor and outdoor applications | Bonds many materials, including fiberglass, wood, concrete, many metals, brick, glass, ceramic, and rubber | Seals oil, gas, and water tank leaks, as well as plumbing and masonry cracks | Fills holes, castings, and molds | Application temperature range is 35 to 115 degrees F, and service temperature range is -20 to +200 degrees F

₹1,13,908.86

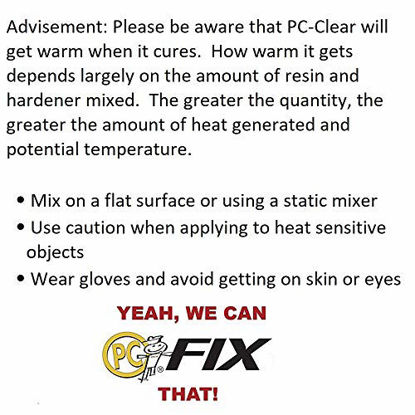

PC Products PC-Clear Epoxy Adhesive Liquid, 1oz Double Syringe, 12-Pack, Clear 70147

Clear epoxy adhesive liquid bonds wood, metal, glass, ceramic, concrete, and fabric | When mixed it turns opaque initially then clear to full cure to blend in with bonded material | Continuous service temperature range from -20 to +200 degrees F | Provides work time of approximately 4 minutes, cure time for function of 1 hour, and full cure time of 24 hours | Forms tough bond for durability

₹7,011.63

PC-Products PC-11 Epoxy Adhesive Paste, Two-Part Marine Grade, 4lb in Two Cans, Off White 640111

Two-part marine epoxy adhesive paste bonds materials in dry, wet, and underwater environments | Bonds many materials, including fiberglass, concrete, many metals, glass, ceramic, and rubber | Can be used in indoor and outdoor applications, with a temperature range of 35 to 115 degrees F and a service temperature range -20 to +200 degrees F | High-tack paste can be used in vertical and overhead applications | Resists mild acids, caustics, detergents, gasoline, fuel oil, and fresh and salt water

₹8,472.94

PC Products PC-Woody Wood Repair Epoxy Paste Kit with Mixing Tool, Two-Part 12 oz in Two Cans, Tan, 63320

Two-part epoxy paste to replace missing or rotted wood is resistant to dry rot, UV light, fresh and salt water | Can be used in indoor and outdoor applications with an application temperature range of 35 to 115 degrees F and a service temperature range of -20 to +200 degrees F | High tack helps reduce drips and sags while hardening | Mix PC-Woody part B mwith PC-Woody part A in equal volumes on a flat surface using the tool included. DO NOT ATTEMPT TO MIX WITH GLOVES | Not recommended to mix PC-Woody in teaspoon size increments or smaller simply because of the likelihood of an ‘off-ratio’ mix

₹3,108.62

PC Products PC-Woody Wood Repair Epoxy Paste, Two-Part 12 oz in Two Cans, Tan

Two-part epoxy paste to replace missing or rotted wood is resistant to dry rot, UV light, fresh and salt water | Can be used in indoor and outdoor applications with an application temperature range of 35 to 115 degrees F and a service temperature range of -20 to 200 degrees F | High tack helps reduce drips and sags while hardening | PC-Woody part B must be mixed with PC-Woody part A in equal volumes on a flat surface with a stiff putty knife; DO NOT ATTEMPT TO MIX WITH GLOVES

₹2,715.11

PC Products PC-Woody Wood Repair Epoxy Paste, Two-Part 24 oz in Two Cans, Tan 44330

Two-part epoxy paste to replace missing or rotted wood is resistant to dry rot, UV light, fresh and salt water | Can be used in indoor and outdoor applications with an application temperature range of 35 to 115 degrees F and a service temperature range of -20 to 200 degrees F | High tack helps reduce drips and sags while hardening | PC-Woody part B must be mixed with PC-Woody part A in equal volumes on a flat surface with a stiff putty knife; DO NOT ATTEMPT TO MIX WITH GLOVES | Not recommended to mix PC-Woody in teaspoon size increments or smaller, simply because of the likelihood of an ‘off-ratio’ mix

₹4,327.32

PC Products PC-Woody Wood Repair Epoxy Paste, Two-Part 48 oz in Two Cans, Tan 643334

Two-part epoxy paste to replace missing or rotted wood is resistant to dry rot, UV light, fresh and salt water | Can be used in indoor and outdoor applications with an application temperature range of 35 to 115 degrees F and a service temperature range of -20 to 200 degrees F | High tack helps reduce drips and sags while hardening | PC-Woody part B must be mixed with PC-Woody part A in equal volumes on a flat surface with a stiff putty knife; DO NOT ATTEMPT TO MIX WITH GLOVES | Not recommended to mix PC-Woody in teaspoon size increments or smaller, simply because of the likelihood of an ‘off-ratio’ mix | Provides work time of 30 to 40 minutes (at 70 degrees F) to allow for adjustments | Can be painted stained and machined after fully cured | High "wet grab" or tack of PC-Woody makes overhead and sidewall work easy without drip or sag | Excellent resistance to all weather elements dry rot UV light fresh and salt water and chemicals present in pressure-treated wood | Note: PC-Woody will not bond to wax paper Teflon Polyethylene and some other plastics Test a small area when in doubt

₹7,764.14

PC Products PC-Woody Wood Repair Epoxy Paste, Two-Part 6 oz in Two Cans, Tan 083338

Two-part epoxy paste to replace missing or rotted wood is resistant to dry rot, UV light, fresh and salt water | Can be used in indoor and outdoor applications with an application temperature range of 35 to 115 degrees F and a service temperature range of -20 to 200 degrees F | High tack helps reduce drips and sags while hardening | PC-Woody part B must be mixed with PC-Woody part A in equal volumes on a flat surface with a stiff putty knife; DO NOT ATTEMPT TO MIX WITH GLOVES | Not recommended to mix PC-Woody in teaspoon size increments or smaller simply because of the likelihood of an ‘off-ratio’ mix

₹2,218.57

PC Products PC-Woody Wood Repair Epoxy Paste, Two-Part 96 oz in Two Cans, Tan 128336

Two-part epoxy paste to replace missing or rotted wood is resistant to dry rot, UV light, fresh and salt water | Can be used in indoor and outdoor applications with an application temperature range of 35 to 115 degrees F and a service temperature range of -20 to 200 degrees F | High tack helps reduce drips and sags while hardening | PC-Woody part B must be mixed with PC-Woody part A in equal volumes on a flat surface with a stiff putty knife; DO NOT ATTEMPT TO MIX WITH GLOVES | Not recommended to mix PC-Woody in teaspoon size increments or smaller simply because of the likelihood of an ‘off-ratio’ mix | Provides work time of 30 to 40 minutes (at 70 degrees F) to allow for adjustments | Can be painted stained and machined after fully cured | High "wet grab" or tack of PC-Woody makes overhead and sidewall work easy without drip or sag | Excellent resistance to all weather elements, dry rot, UV light, fresh and salt water and chemicals present in pressure-treated wood | Note: PC-Woody will not bond to wax paper Teflon Polyethylene and some other plastics Test a small area when in doubt

₹9,884.22

PC-Products Wood Repair Epoxy Paste and Wood Hardener Kit, PC-Woody 6 oz and PC-Petrifier 8 oz

8 oz PC-Petrifier water-based wood hardener with 6 oz PC-Woody wood repair in a convenient bundle for all wood repair projects | Use PC-Petrifier liquid wood hardener to strengthen seal and harden deteriorating wood | PC-Petrifier will penetrate deep into decaying wood to restore window sills frames beams columns and trim | After repairing wood damage with PC-Petrifier use PC-Woody two-part epoxy paste to replace and fill damaged wood | PC-Woody fills gaps in wood window sills frames doors rails and can be painted stained and machined after fully cured

₹3,459.65